Rolling stock components

The general series of components provides enough components for at least three wagons. Some specialised items provide only parts for one wagon.

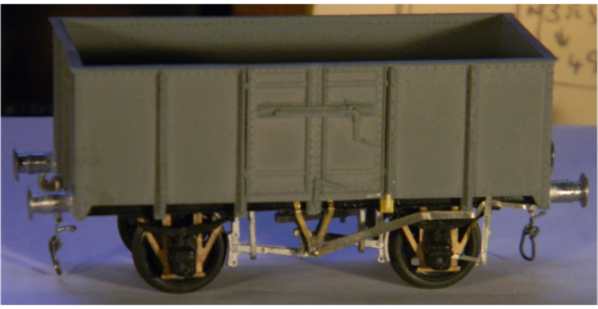

The illustration below right is of a 7mm wagon kit with new underframe components from the test etchings.

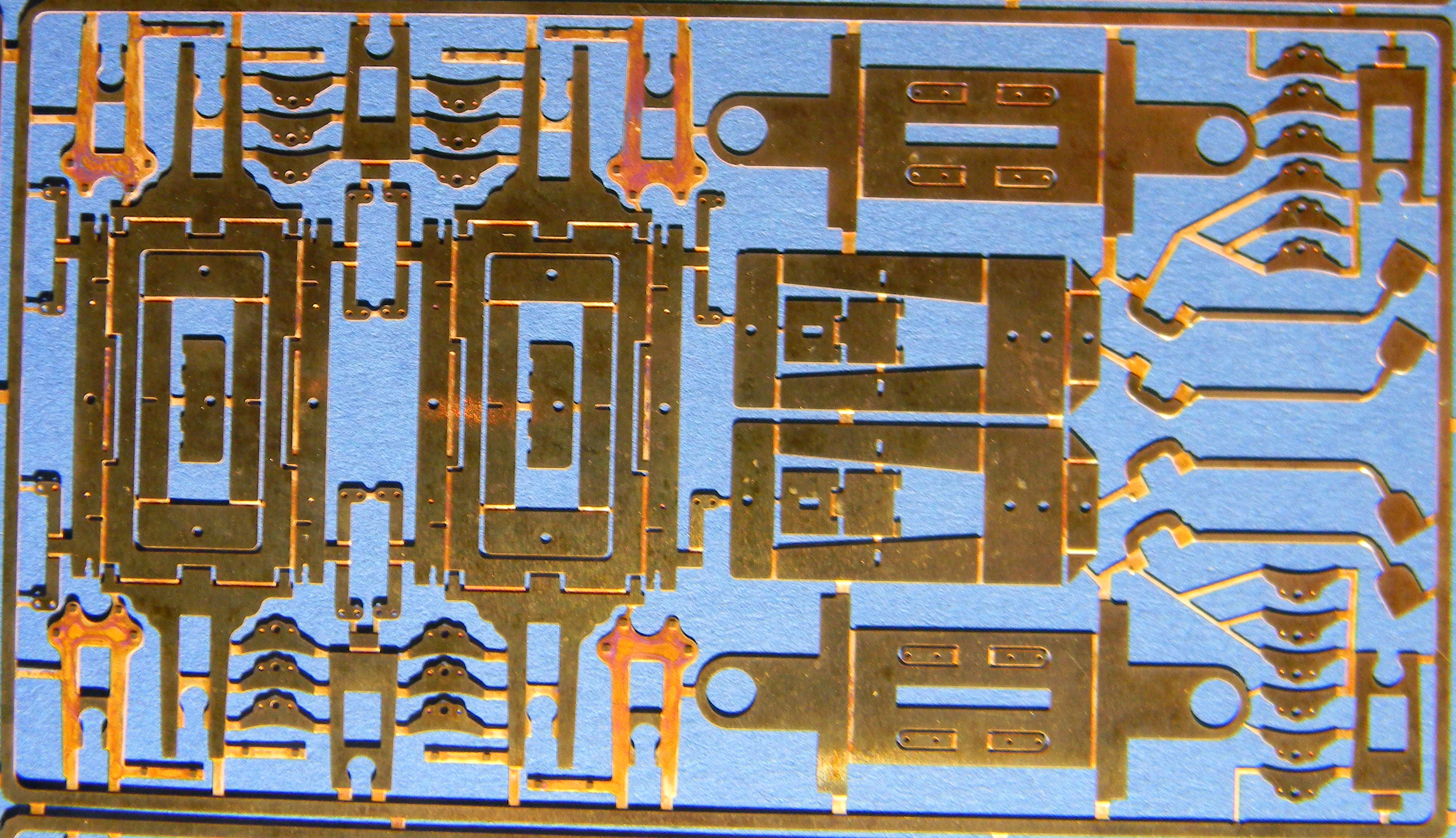

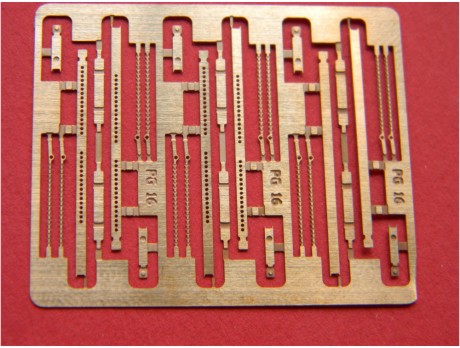

Above left is the test etch for wagon underframe components in 4mm scale.

The first components in this range were to allow brake levers and their guides or guards to be replaced. The AMBIS brake lever guides have had a checkered life as the preferred material become unavailable and an alternative design was tried but was not sucessful. In 2008 the new series of brake lever guides were introduced starting from NE hopper wagon designs. These have been followed by other versions which will resulted in 14 different patterns being produced.

Brake levers are now in their fifth series. Each series incorporates minor design changes, such as the Moreton link (when appropriate) being attached to the main lever etch - the early version was very fiddly to assemble, or the half etching of the brake lever to give a tapered product. Finally the later versions include one pattern of lever per etching - the first series contained four different shapes to replace damaged old plastic or white metal wagon items and was finally withdrawn in7mm:1 foot scale in 2012.

The original brake lever design was to allow the whole brake lever assembly to work, if required. Now to do this you need to disassemble the etch if you want the brakes to work.

From the fourth series the modeller should reproduce a taper in the lever by filing away the lever down to the half etched handle end. The usual material used is .015" thick whereas the handle would be around 1.5 inches in prototype thickness, by thinning down the handle end would result in less than 3/4" thickness which is more appropriate and much easier to shape.

A mixture of components from many sources, the basis wagon being a repaired Parkside-Dundas model. AMBIS parts are the coupling hooks and links, the brake lever (BL3K) and the mk.1 one brake lever guide.

A mixture of components from many sources, the basis wagon being a repaired Parkside-Dundas model. AMBIS parts are the coupling hooks and links, the brake lever (BL3K) and the mk.1 one brake lever guide.

To complement brake levers an etching of standard wagon "Vees" was introduced incorporating most of the strapping visible on wooden solebar wagons. Other Vee designs are in production, whilst a subset of brake levers in the Vees range focuses on lifting link brake variations.

To accommodate different wheelbase wagons a range of push rods were introduced which the modeller can adapt, using the adjustment holes, to set up the clearance they need between wagon wheel and brake block. This currently can range from 8 feet to 17 feet 6 inch wheelbases - with equal length push rods. In order to achieve the small adjustment holes the material used for push rods is thinner than the other parts of the wagon components.

Some unequal length push rods and other brake application systems were introduced that are general designs, such as used by L&Y railway and British Railways clasp brake.

It is unlikely that a wagon specific product will be introduced.

The final etching component is brake blocks. These are made up from several layers, but it is possible to use the etch part as a detail overlay to a cast or moulded push rod/brake block component from another source. Early brake blocks were handed/single sided, later versions such as specified in the RCH 1923 standard required brake blocks to be used at any location - for ease of maintenance. This component has many varied alternative shapes and alternative brake blocks or shoes have been produced for particular wagon designs.

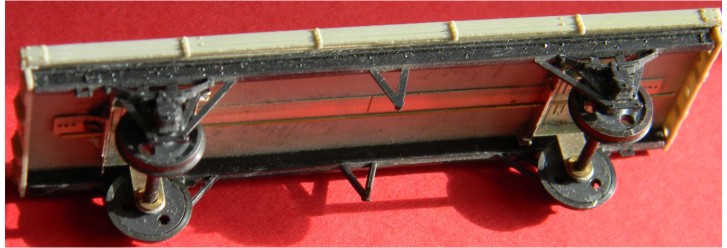

Above a number of BR era wagons, firstly a converted 16T mineral wagon followed by two plastic body iron ore tipplers with new underframes from AMBIS test etches for the iron ore tippler etches.

Some wagon manufacturers used particularly distinct design features and these will be introduced as opportunities occur.

After the first Railway Clearing House (RCH)/Midland Railway design for axleguards was introduced further distinctive designs were added to the range. Currently standing at 17 different shapes this range will be added to as circumstances permit. The principles that have been adhered to is that the range will, if at all possible, allow wheelsets to be sprung, compensated or fixed.

An early kit for the LMS Long Low wagon with flexible inside bearing axles. The axlebox and axleguard mouldings have not been modified.

For longer wheelbase wagons AMBIS suggests that the axles rotate across the longitudinal axis of the wagon. As the heavy duty RCH/LMS, LNWR/NSR early narrow plate and GNR/LNER wide axleguards (AX3, AX9 and AX10 products) have been redrawn these now include the long wheelbase option for wheelbases greater than 12 feet.

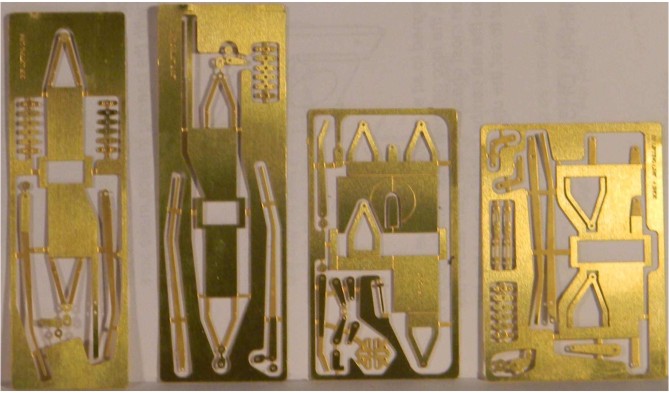

The AX9 axleguards set for two axles and LWBO_C set for three axle rolling stock includes optional outside (the leaf spring) four bolt axleguards, brake blocks and truss rod components as well as the flexible axle and inside bearing options. Below is shown a number of the Vee hanger and brake lever etches. The LSWR version (second from left) was redrawn with the correct third "Vee" in January 2016.

This is a sample of the brake lever guides etching - the 7mm@1 foot scale version.

Some specific wagon body strapping kits have been produced as a precursor to other products. These are for unusual Midland Railway wagons, the tariff van - a variation on the 10T goods van (D382) , a version of the tariff brake Van (D392) - otherwise similar to the 10T 4 wheel brake van and the intermediate size 4w 20T "single ended" brake van (D1045) which can be produced from the later doubled ended brake van. All starting vehicles can be made from available plastic wagon kits.

As part of the window improvement programme a number of push fit windows for thick sided coaches will be introduced. Plastic mouldings tend to have a small taper, normally invisible otherwise they will not release from moulds very cleanly, it may be necessary to remove at least part of any taper to allow the replacement windows to snugly fit. Furthermore it is not certain that all plastic mouldings will always have the exactly the same window dimensions so it may be necessary to gently enlarge some openings for every window to be installed.

References

1) All prototype railway wagon books - upwards of 35 titles

2) The books on private owner wagons - upwards of 15 titles

3) On-line picture libraries such as Paul Bartlett's "Wagons on the Web"